Building Information Modeling

Gibson Electric’s virtual construction department boasts more than 40 years of combined building information modeling (BIM) experience.

Because our advanced BIM technology is tightly integrated into our work processes, we’re able to avoid rework, identify constructability issues, leverage prefabrication opportunities, and communicate effectively with internal teams and external contractors.

Leveraging BIM for Success

For BIM coordination to work properly, it needs to be effectively communicated to installation and construction teams in the field. By utilizing laptops and portable hand-held devices, we help ensure this happens, supplying our foreman with the latest information in real-time.

For BIM coordination to work properly, it needs to be effectively communicated to installation and construction teams in the field. By utilizing laptops and portable hand-held devices, we help ensure this happens, supplying our foreman with the latest information in real-time.

Additionally, all contract documents, installation drawings, field layout points, markups, and 3D models are hosted in the cloud for rapid access—anytime, anywhere. We even go a step further by providing training in each of these technologies to all foremen and office personnel.

Model-Based Prefabrication for Rapid Construction

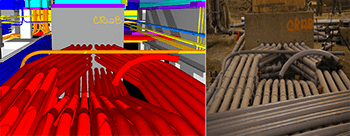

Our BIM team uses Autodesk Revit to create intelligent models, allowing our shop to pre-fabricate electrical panels, junction boxes, hangers, conduit bends, strut assemblies and more. Pre-fabrication helps us shorten installation schedules while improving safety and quality control.

Additionally, customers often look to us to run or assist BIM coordination for all subcontractors on mission critical projects. Backed by long-standing industry relationships, we take a collaborative approach to help ensure BIM supports construction schedules while allowing coordinators to work quickly and efficiently.